Cutting Smart Film PDLC (used in LCD displays, smart glass, etc.) requires balancing precision and efficiency, as edge quality directly impacts optical performance. Below is a structured guide to optimize the process:

-

1. Preparation and Tool Selection

Material Fixation & Alignment

- Secure the film on a vacuum adsorption platform or anti-static mat to prevent slippage.

- Use laser alignment markers or optical projectors to ensure the cutting direction aligns with the film’s layered structure (e.g., conductive layer, liquid crystal layer), minimizing delamination risks.

Tool Recommendations

- Precision Blades: Ultra-thin tungsten carbide blades (e.g., OLFA) for manual cutting. Replace blades frequently to avoid jagged edges.

- Laser Cutters: CO₂ lasers (10.6μm wavelength) are ideal for non-contact cutting. Adjust parameters based on film thickness:

- Example: 100μm PET-based film → Power: 30W, Speed: 10mm/s, Frequency: 1kHz.

- Die-Cutting Machines: Suitable for mass production. Optimize steel mold angles (25°–30°) and pressure (0.3–0.5MPa) to prevent deformation.

2. Cutting Process Optimization

- Environmental Control

- Maintain temperature at 20–25°C and humidity at 40–60% to avoid thermal expansion or moisture-induced dimensional errors.

Path Planning & Edge Quality

- Use vector-based continuous cutting paths in CAD designs to minimize start-stop marks.

- For complex shapes, design micro-connection points (0.1–0.2mm uncut areas) to simplify waste removal.

- Post-cut edge treatment: Polish with 2000+ grit sandpaper or use plasma treatment to eliminate burrs.

3. Automation and Smart Technologies

- Machine Vision Systems: CCD cameras enable edge detection with ±0.05mm accuracy.

- Parameterized Programming: Pre-set cutting parameters for common film thicknesses (50–200μm) and integrate robotic arms for roll-to-roll production.

- Real-Time Monitoring: Force sensors adjust blade pressure dynamically to prevent over-cutting or incomplete cuts.

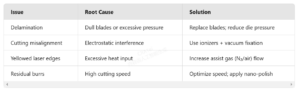

4. Troubleshooting Common Issues

5. Quality Inspection and Post-Processing

- Optical Testing: Use a transmissometer to check for uniform light transmission. Polarizer rotation tests reveal edge defects (e.g., light leakage).

- Functional Verification: Sample electrical testing to ensure response time <1 second. Damaged electrodes from poor cuts may cause circuit failures.

Final Notes:

- For small batches, prioritize manual techniques with sharp blades and meticulous alignment.

- Automated systems excel in high-volume production but require rigorous parameter calibration.

- Always combine optical and electrical tests to validate performance.

Adopting these strategies ensures efficient, high-precision cutting while maintaining the functional integrity of Intelligent Film .

Post time: April 27th 2025